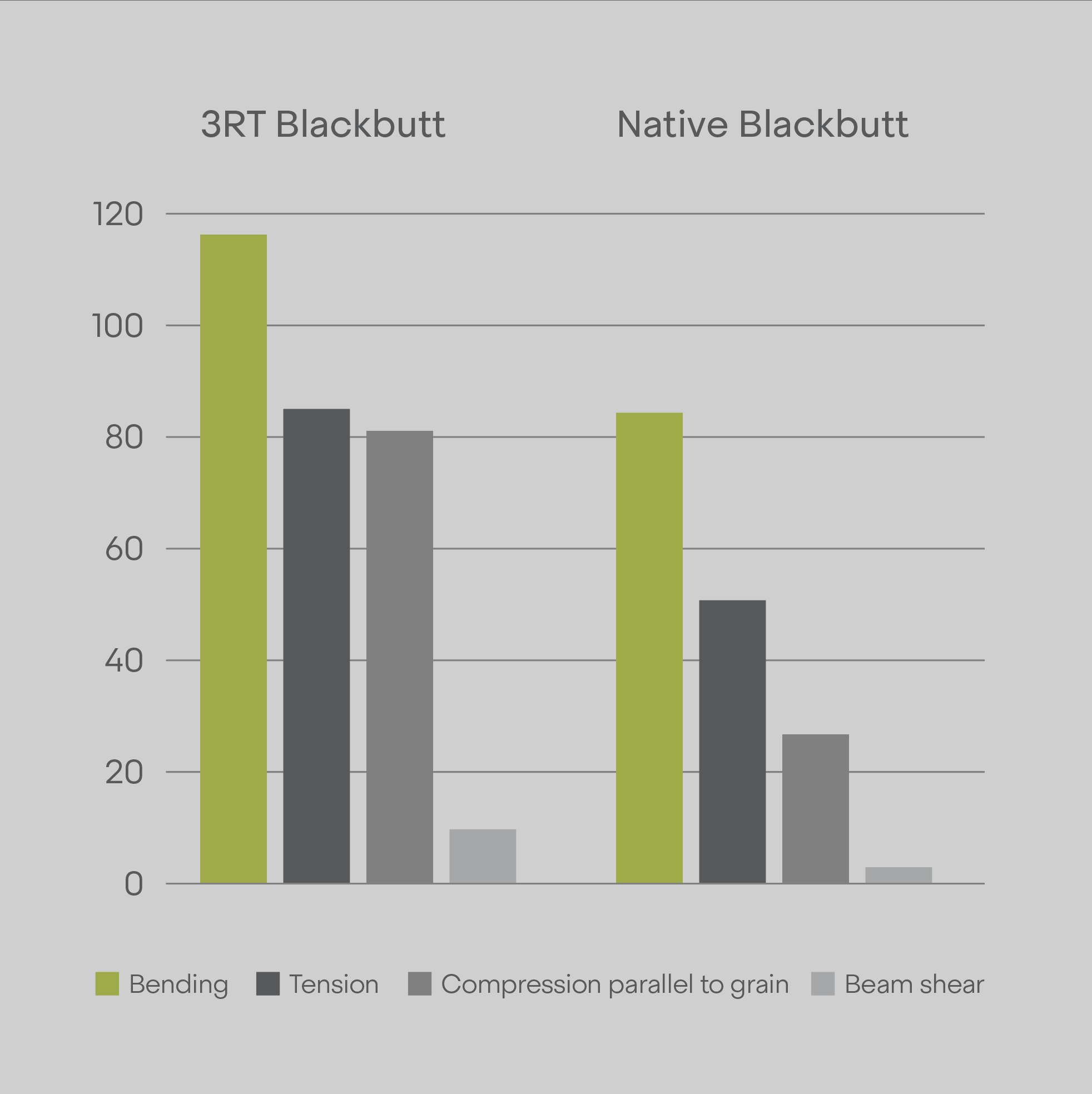

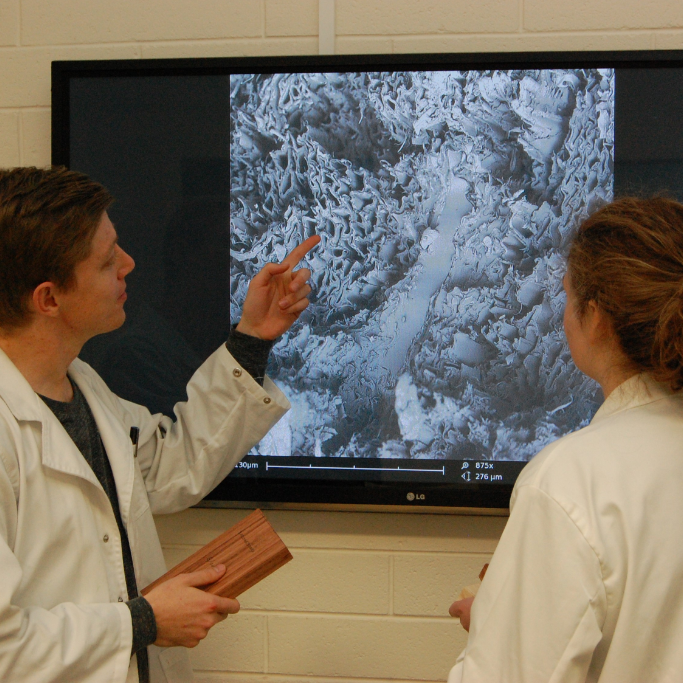

Our technology converts low value plantation logs into new hardwoods with the look, feel and properties of 100-year old trees in one day.

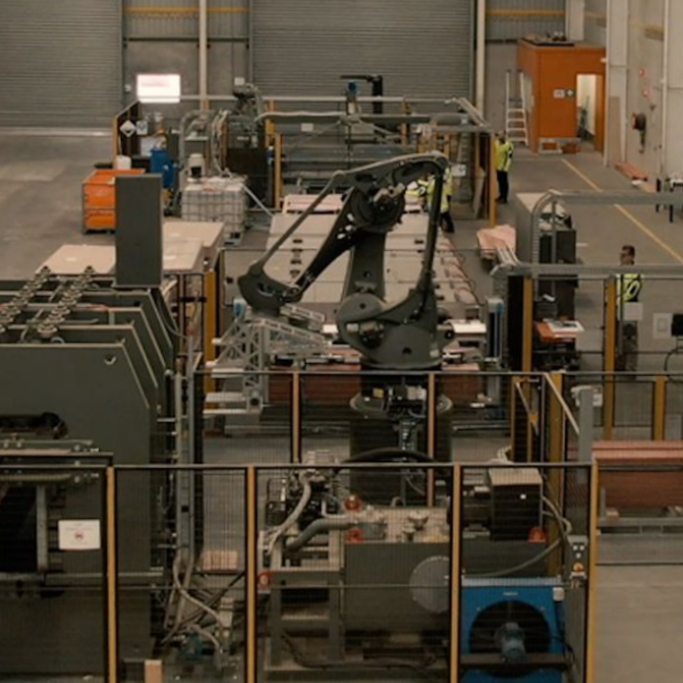

Advanced Robotics and Smart Automation allow for efficient and fast manufacturing using local wood residues anywhere on earth. So our global technology platform can provide local solutions to local markets (“mass customisation”).